-

+91-9619444576 -

HITRATNA@YAHOO.COM

Preferred Buyer From

| Location | Worldwide |

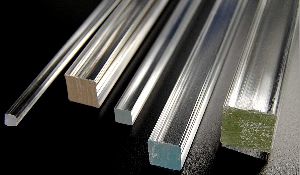

To minimize the human interference, we have incorporated automated systems and thus, we are capable of maintaining high standards in terms of quality, space or delivery of the products. Over the years, we have emerged as a noteworthy Supplier offering a huge array of Round Bars.

Application :

Machined Components, Pump Shafts, Valves, Fasteners, Machine Tools, Dairy Equipments, Surgical & Medical Parts, Threaded Bars, Studs, Bolts, Pins, Hinges and Handles.

Specification

| Condition | Cold Drawn & Polished | Cold Drawn, Centreless Ground & Polished | Cold Drawn, Centreless Ground & Polished (Strain Hardened) |

| Grades | 20, 202, 303, 304, 304L, 310, 316, 316L, 32, 410, 420, 416, 430, 431, 430F & others | 304, 304L, 316, 316L | |

| Diameter (Size) | 2 mm to 5mm (1/8" to 3/16") | 6mm to 22m (1/4" to 7/8") | 10mm to 40mm (3/8" to 1-1/2") |

| Diameter Tolerance | h9 (Din 671),h11 ASTM A 484 |

h9 (Din 671) ASTM A 484 |

h9 (Din 671),h11 ASTM A 484 |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm (-0 ”/+1 feet) |

We can give Chamfering of 30 or 45 degrees on one or both the ends with our dedicated chamfering machine. For Strain-Hardened Bars, we can supply in B8(304) and B8M(316) in Class1 and Class2.

Round Bar (Peeled/Tuned)

| Condition | Peeled, Centreless Ground & Polished | Peeled & Polished | Peeled (Rough Turned) |

Forged, Rough Turned |

| Grades | 20, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 420, 416, 430, 431, 430F & others | 304, 304L, 316, 316L, 410, 416, 420, 431 | 303, 304, 304L, 316, 316L, 410, 416, 420, 431 | |

| Diameter (Size) | 20mm to 85mm (3/4 ” to 3--1/4 ”) |

85mm to 140mm (3-1/4 ” to 4--3/4 ”) |

25mm to 140mm (1 ” to 5--1/2 ”) |

150mm to 400mm (6 ” to 16 ”) |

| Diameter Tolerance | h9 (Din 671) ASTM A 484 |

h11 | K12/K13 (Din 1013) |

-0mm/+3mm (-0 ”/+0.12 ”) |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) |

3 meter -5 meter 10 feet -16 feet |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+1000mm or 500mm (-0 ”/+3 feet or +2 feet) | -0/+2 meter- -0/+6 feet |

We can give superior surface finish and straightness tolerance for Pump Shaft Quality by additional processes such as straightening,roller burnishing,and centreless grinding.Bars can be packed in wooden boxes,with each bar protected with plastic rings to avoid bending and scratches.